Today, battery technology is developing at a breath-taking pace. Nevertheless, your customers’ expectations for safety and quality are as demanding as always. Battery testing addresses these by validating the safety and reliability of the batteries used in a growing range of applications. This includes batteries for transportation applications such as electric vehicles, rail, marine and aerospace, but also stationary batteries for grid storage and balancing, backup power applications and batteries for wireless equipment and medical devices.

As a professional mechanical testing equipment manufacturer, we should know it must protect the cell or pack within, and be able to withstand high shock, vibration and impact loads.

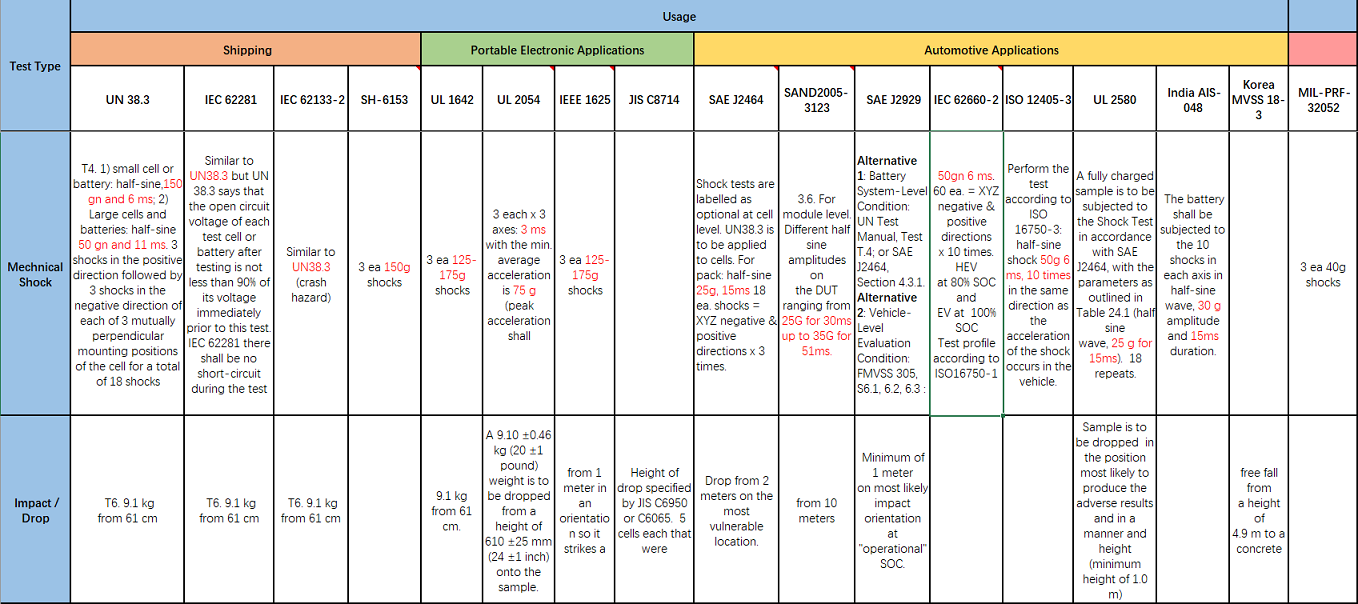

Many customers ask for equipment meet different battery testing standards rather than giving us the direct test specifications, we need check each standard and then propose the suitable model or customize model.

CME is capable of offering equipment for mechanical shock and drop testing. Today we mainly explain how to choose mechanical shock test machines.

Before we propose, if customer already gave out the standards, then:

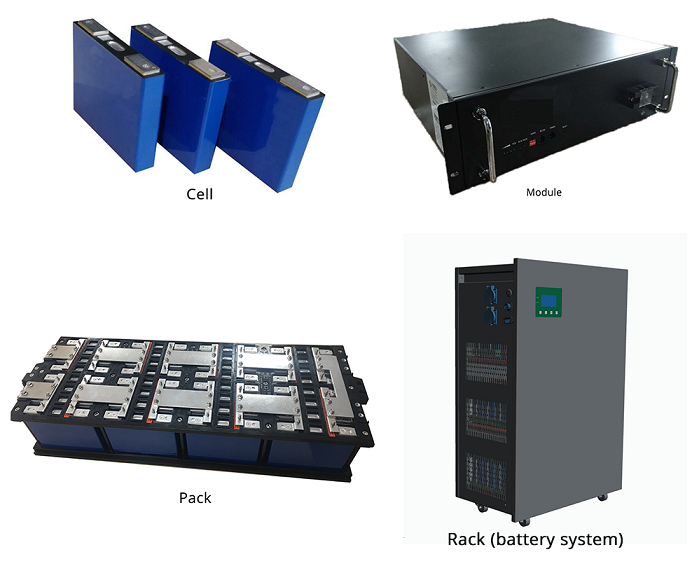

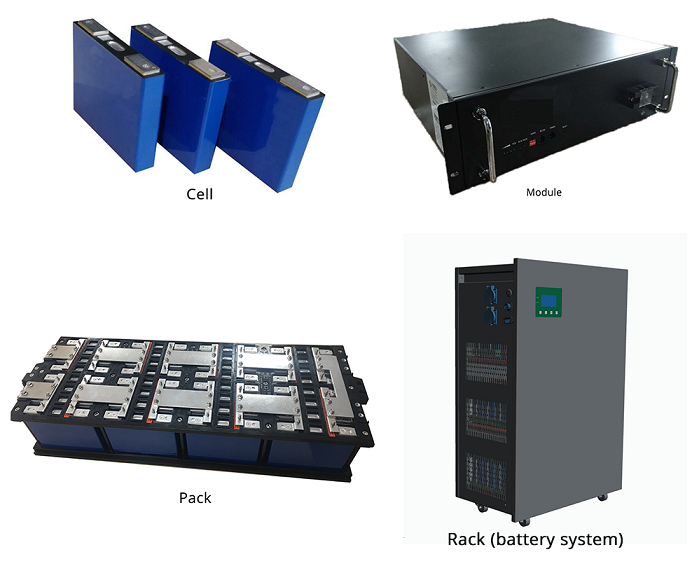

We need to check the battery types, since they have corresponding test specifications:

1. Cell

2. Module

3. Pack

4. Rack (battery system)

Check the battery specifications:

1. Size

2. Weight

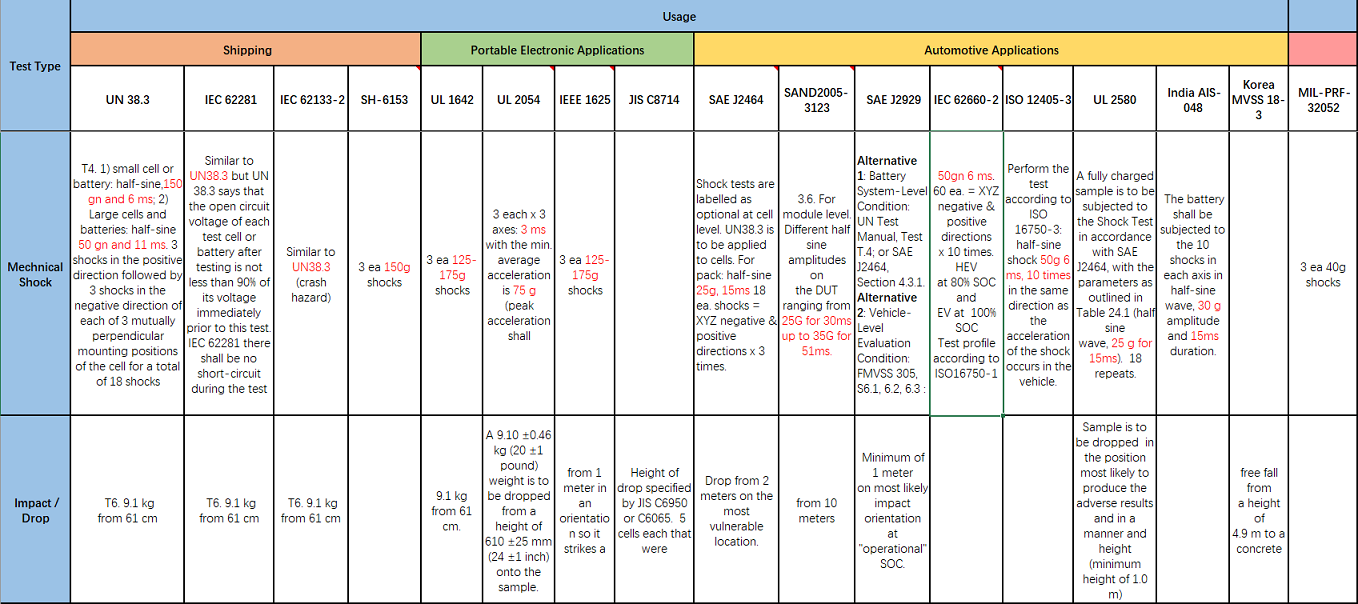

If customer didn't give out the standards, but want to do check which standards he should do, we need check one more thing:

The usage of battery:

1. Shipping

2. Portable Electronic Applications

3. Automotive Applications

4. Military Applications

CME sort out some main standards as following:

Most batteries for Portable Electronic Applications are only requested by cell testing, with limited weight and size, we recommend KRD11 vertical shock test system.

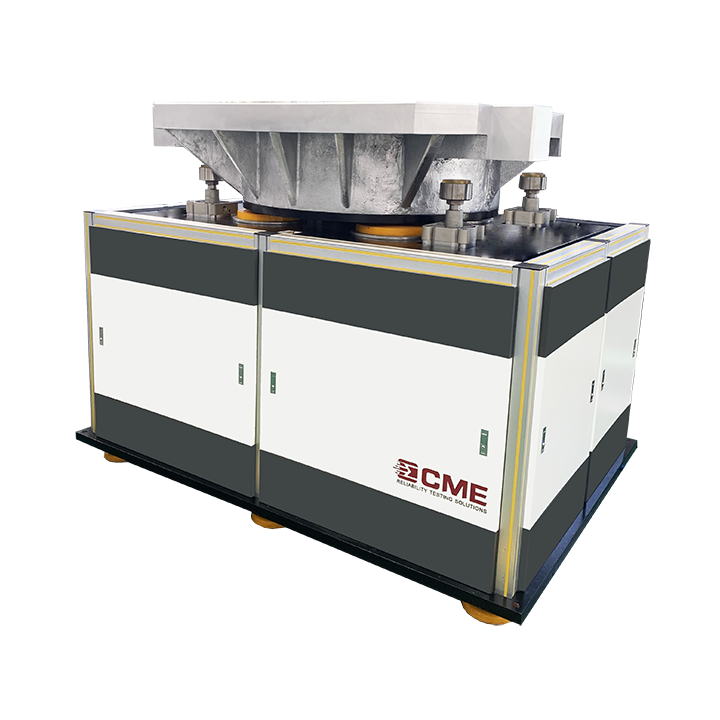

KRD11 Vertical Shock Test System

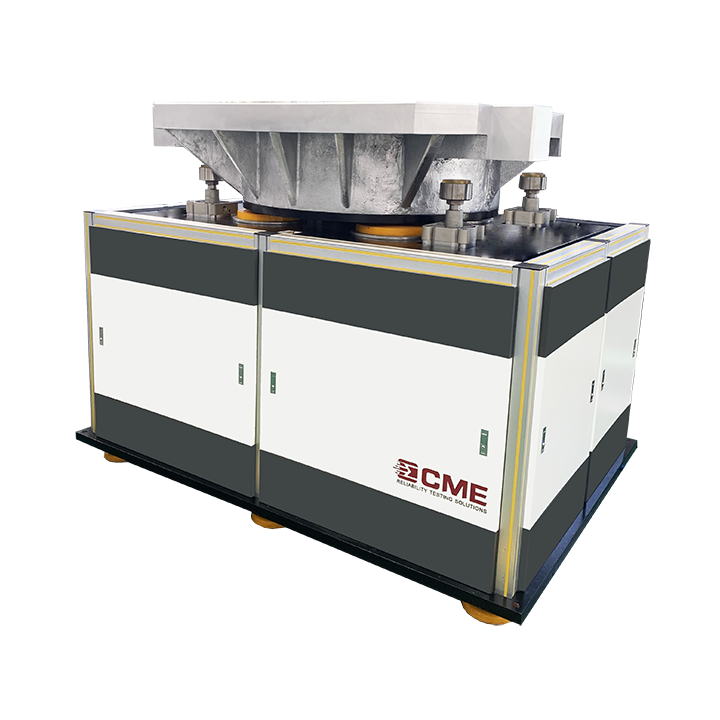

General battery packs for both automotive and energy storage application are more than 500kg, we recommend use KRD20 bump test machine (also can-do shock test) or KRD13 high acceleration shock test system. KRD20 bump test machine is suitable for large size battery pack, and with middle acceleration and large pulse duration, such as:

1. 16g~60ms

2. 24g~16ms

3. 25g~15ms

4. 50g~11ms

5. 50g~15ms

KRD13 is specialized for high-energy shock testing, KRD13 is capable of doing following test:

1. 60g~45ms

2. 24g~50ms

3. 90g~20ms

4. 150g~15ms

5. 70g~45ms

6. 300g~11ms

7. 200g~10ms

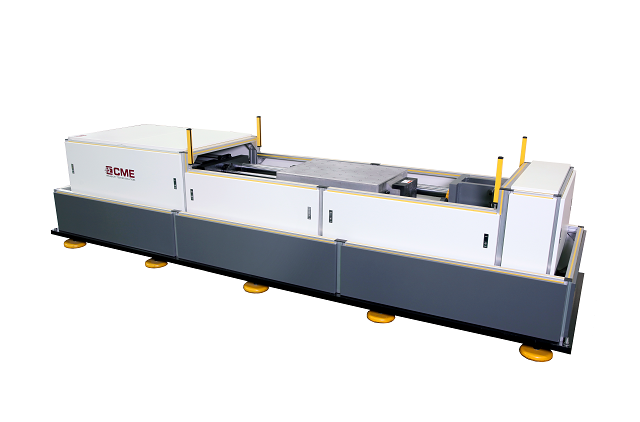

KRD20 Bump Test Machine KRD13 High Acceleration Shock Test System

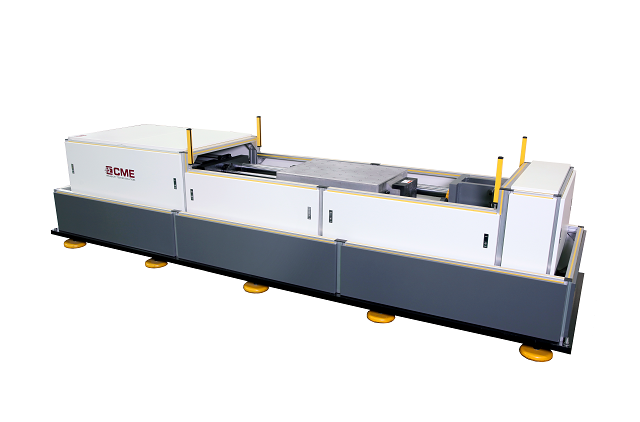

At last, if customer only request horizontal direction shock test or he has additional budget to purchase horizontal shock test system, then KRD12 horizontal shock test system is the perfect choice to do all above test.

KRD12 Horizontal Shock Test System

If you have more questions on "how to choose battery shock testing equipment", we welcome you to contact us: [email protected].