Overview of constant acceleration test

The performance of product, in addition to its own inherent technological advancement, adaptability to the use environment, reliability and environmental resistance during actual use and transportation are components that cannot be ignored that affect the performance of military equipment. In order to improve the technical level of military equipment and improve the reliability of military equipment, various reliability tests for military equipment have been extensively carried out in the development and production of equipment, including dynamic constant acceleration tests.

Any product has to go through various links such as production, circulation, and use. Products installed on transportation vehicles, aerial vehicles, rotating machinery and projected objects must work under conditions of large constant acceleration. Whether it can work normally under the predetermined constant acceleration conditions must be assessed through certain experiments. The constant acceleration will cause the inertial force of the flying mass, which makes the aircraft, spacecraft and carrying objects appear overweight or weightless.

Different products, similar products with different structures, to determine and compare the pros and cons of their ability to resist constant acceleration, a method must be used for comparison and evaluation. Therefore, assess whether the structure of the product is damaged under high acceleration conditions, and verify the integrity of its structure through tests. In abnormal use, such as forced landing of airplanes, emergency braking of vehicles, ships, etc., the constant acceleration value is abnormal. At this time, whether equipment, parts and components fall off, causing injury to the occupants and hindering the normal operation of their safety and life-saving equipment, must be passed test to verify its crash safety.

Why do constant acceleration test

IEC 60068-2-7, MIL-STD-810 and MIL-STD-202, MIL-STD-883, MIL-STD-750 all take steady-state acceleration (constant acceleration) test as one of the key tests of electronic equipment.

To prove the structural suitability equipment and other electrotechnical when subjected to forces produced and the satisfactory performance of components, products, hereinafter referred to as “specimens”, by steady acceleration environments (other than gravity) such as occur in moving vehicles, especially flying vehicles, rotating parts and projectiles, and to provide a test of structural integrity for certain components.

MIL-STD-810 Test Method 513The acceleration test is performed to assure that materiel can structurally withstand the steady-state inertia loads that are induced by platform acceleration, deceleration, and maneuver in the service environment, and function without degradation during and following exposure to these forces. Acceleration tests are also used to assure that materiel does not become hazardous after exposure to crash inertia loads.

This test method is applicable to materiel that is installed in aircraft, helicopters, manned aerospace vehicles, air-carried stores, and ground-launched missiles.

MIL-STD-883 Test Method 2001This test is used to determine the effects of constant acceleration on microelectronic devices. It is an accelerated test designed to indicate types of structural and mechanical weaknesses not necessarily detected in shock and vibration tests. It may be used as a high-stress test to determine the mechanical limits of the package, internal metallization and lead system, die or substrate attachment, and other elements of the microelectronic device. By establishing proper stress levels, it may also be employed as an in-line 100 percent screen to detect and eliminate devices with lower than nominal mechanical strengths in any of the structural elements.

MIL-STD-202 Test Method 212This test is performed for the purpose of determining the effects of acceleration stress on component parts, and to verify the ability of the component parts to operate properly during exposure to acceleration stress such as would be experienced in aircraft, missiles, etc. Unless otherwise specified, the acceleration test apparatus shall be the centrifuge-type and shall be capable of subjecting the test specimen to the value of acceleration (g’s) as specified in.

The constant acceleration test is used to determine the effect on semiconductor devices of a centrifugal force. This test is an accelerated test designed to indicate types of structural and mechanical weaknesses not necessarily detected in shock and vibration tests.

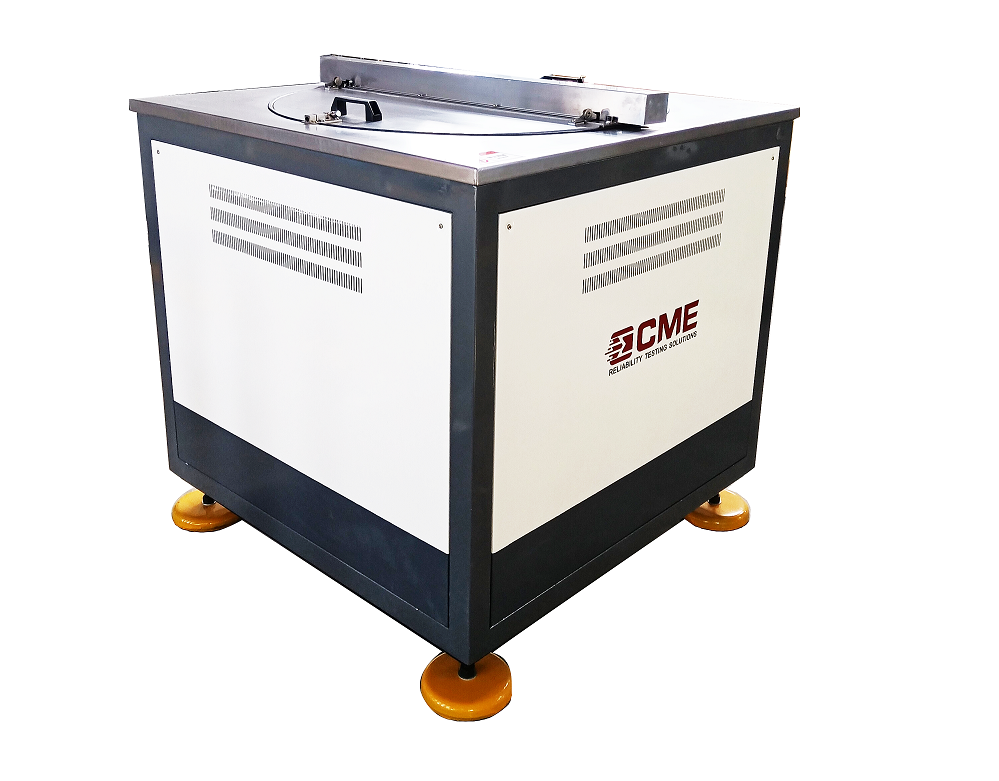

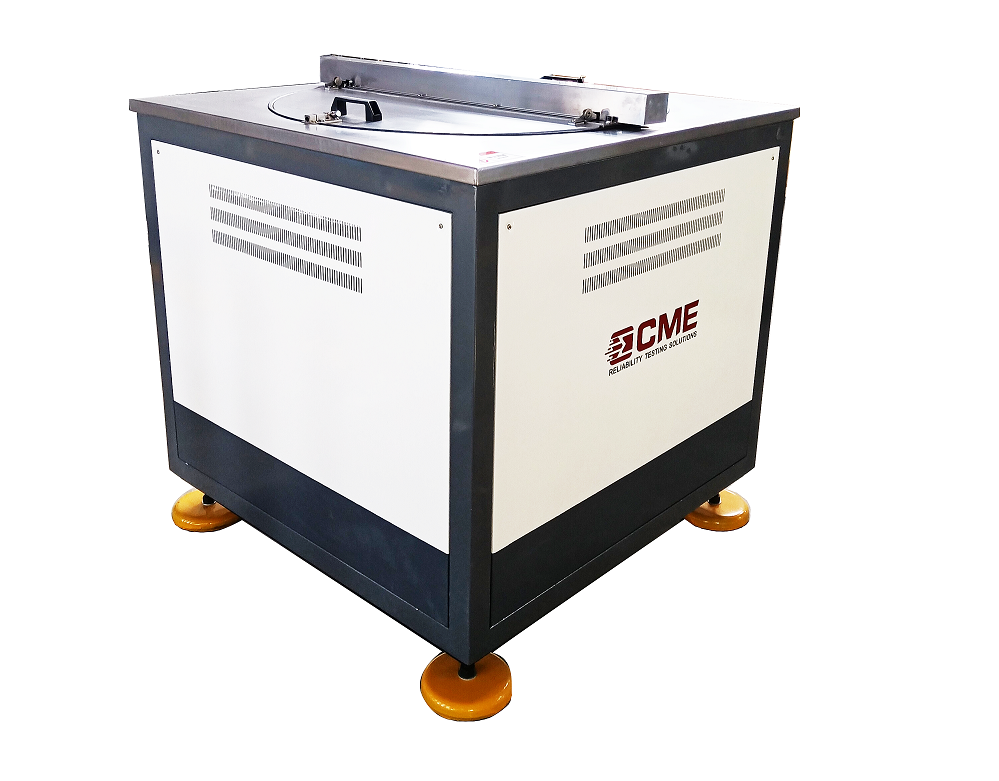

CME centrifugal constant acceleration tester

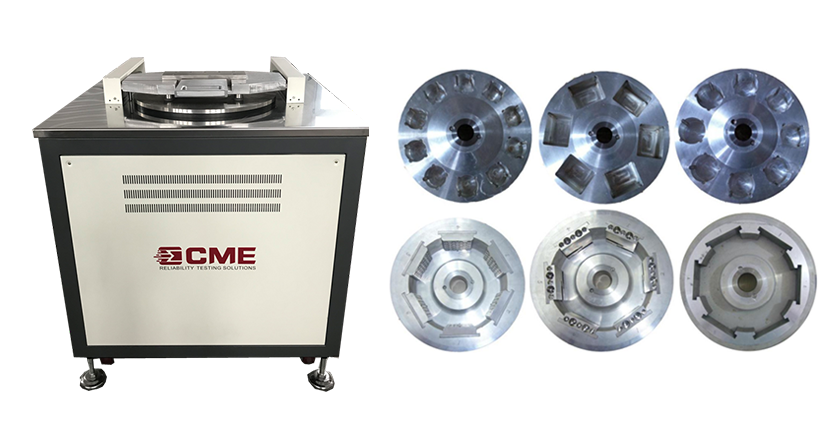

There are two standard types of centrifugal constant acceleration testing machines. One is the centrifugal box type, which is suitable for the constant acceleration test of small electronic components and microelectronic devices; the other is the centrifugal arm type, which is suitable for the constant acceleration test of electrical and electronic product components and small complete machines.

CME can provide the following three kinds of constant acceleration tester

KRD30 Constant Acceleration Tester (Box Type)

KRD31 Constant Acceleration Tester (Arm Type)

KRD32 Non-standard Constant Acceleration Tester

Full-automatic computer remote real-time control interface. The operator only needs to input simple values to start the equipment and complete the acceleration test accurately.

User-friendly display interfaceThe control interface can display the test curve, tolerance and test time in real time.

Powerful multi-acceleration continuous test systemIt can realize multi-level acceleration continuous test according to the different requirements of the test sample.

Reliable protection measuresOpen circuit, over-limit and over-speed protection can be realized.

In the case of automatic control failure or no need of automatic control, the device can still use manual control to complete the test

Convenient and quick result output systemAfter the test, the test report is automatically generated and printed out.

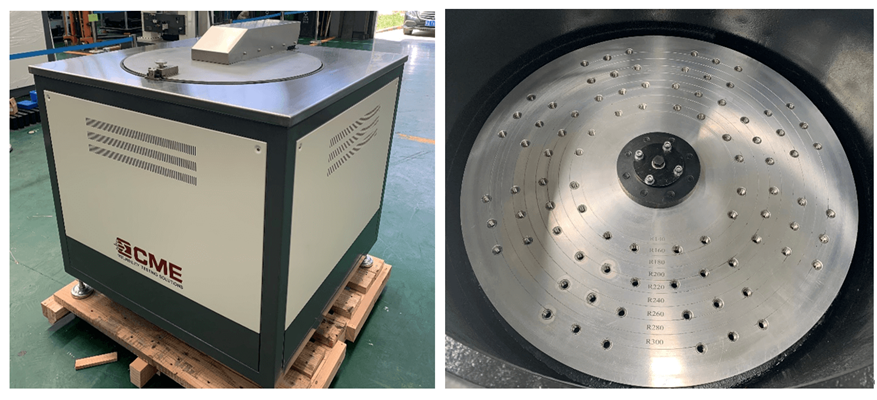

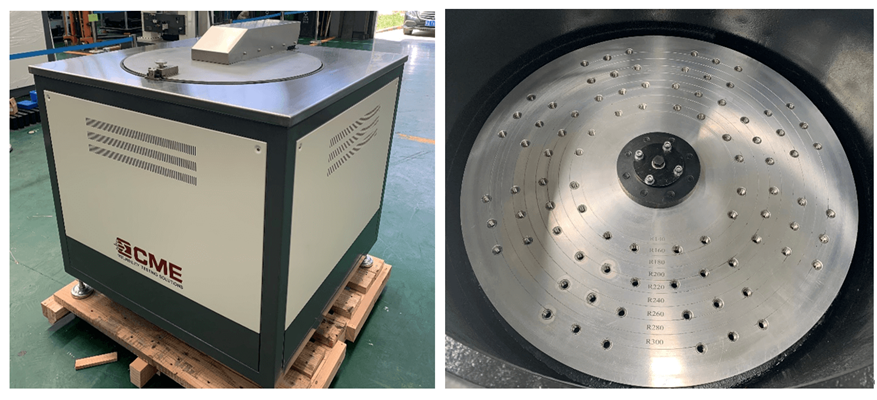

KRD30 Constant Acceleration Tester (Box Type)

KRD30 series constant acceleration test machine is used to evaluate when components, equipment and other electrical and electronic products are subjected to constant acceleration environment (except gravity), whether the structure adaptability and performance are good, and obtain the units’electrical parameters.

KRD30-03/05: it is a small standard rotation turntable centrifuge. KRD30-03 is six-station and KRD30-05 is four-station. The number of stations can be customized, the total load does not exceed 20kg, and the acceleration is up to 500g.

KRD30-10/20: it is a small arm centrifuge, both models are two-station, the maximum acceleration is 100g.

KRD30-2M/3M/4M/8M: Multi-station high-acceleration turntable centrifuge with vacuum system, easy to achieve high-speed operation, acceleration up to 80,000g

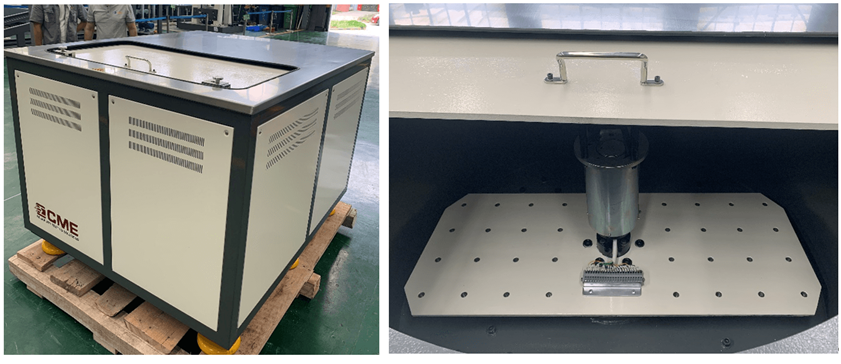

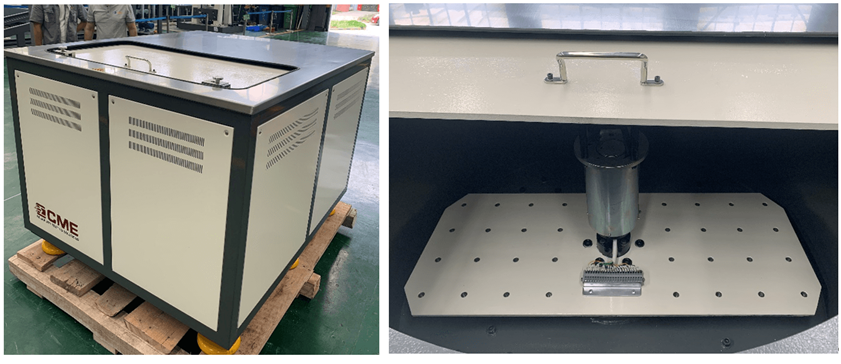

KRD31 Constant Acceleration Tester (Arm Type)

KRD31 series constant acceleration tester are used to test articles under extreme acceleration conditions based on standard like MIL-STD-810F, MIL-STD-202 and IEC68-2-7.

It is most suitable for testing electronic components or devices. Under high g effect on microcircuits, to check adaptability and reliability of wiring and the internal structures. It may expose mechanical and structural defects that are not found with vibration and shock tests.

Specifications:

- Max. load: 3000Kg

- Max. acceleration: 100g

- Max. arm length: 14m

- Acceleration accuracy: ≤±3 (%)

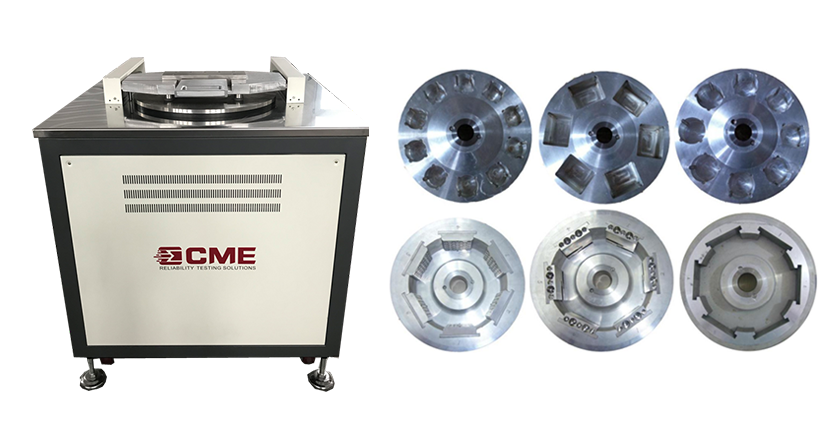

KRD32 Non-standard Constant Acceleration Tester

KRD32 series non-standard constant acceleration testing machine is test equipment for military products to simulate dynamic centrifugal motion, dual-environmental force centrifugal motion and central high-speed rotating motion, so as to assess the anti-load performance of electronic components, small components and other electrical and electronic products and detect the anti-load performance specifications. It is mainly used for routine dynamic structural integrity and adaptability tests of components, small partsand small complete machine on aircraft.

KRD32-1Dual-environment constant acceleration tester

This type of centrifuge provides a platform for the sample to revolve and rotate, that is, while the sample is rotating, it revolves around a fixed axis of a certain radius. It is called a dual-environment centrifuge or dynamic overload testing machine.

KRD32-2 High-speed spin tester

This type of centrifuge is driven by an electric spindle to achieve the required speed. Commonly used for centrifugal tests of batteries. According to different test requirements, it can be roughly divided into 15,000 rpm, 20,000 rpm, 30,000 rpm and 50,000 rpm centrifuges. The load of this type of equipment is generally small, and the size of the sample is also small.

KRD32-3 Centrifugal dynamic overload tester

Maximum load 50Kg, maximum acceleration 20g.

KRD32-4 Spin shock compound tester

This type of centrifuge is mostly used to simulate the real motion state of missiles or shells after launching, that is, the sample is rotated at high speed while making it bear sufficient shock acceleration and overload. Generally, it is a high-speed spinning centrifuge. A composite test system composed of a high acceleration shock table.

KRD32-5 Centrifugal vibration compound tester

This type of centrifuge is urgently needed environmental testing equipment in the fields of geotechnical technology, earthquake simulation and aerospace. For example, when the spacecraft is orbiting the earth, when the aircraft is climbing, diving and hovering, and when the strategic missile is in the active phase and passing through the reentry phase, its internal equipment and devices are subjected to the combined action of acceleration overload and engine vibration. Its basic structure is to load the shaking table on the rotating arm of the centrifuge, so that the sample is subjected to the centrifugal constant acceleration test at the same time during the vibration test. This system can also be extended to a comprehensive test system of centrifuge, vibration table and climate chamber.

If you need centrifugal constant acceleration test equipment, please contact us!