Abstract

Through the analysis of the basic parameter characteristics of the centrifuge acceleration direction, acceleration value, velocity ripple, acceleration gradient, etc., effective methods for the design, use and measurement of the centrifuge are obtained.

Calculation of basic parameters of centrifuge

1. Centrifugal acceleration

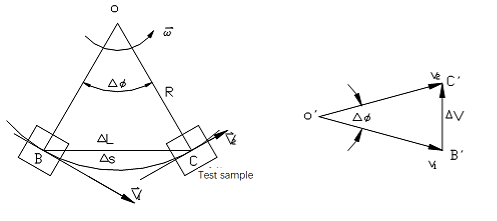

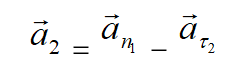

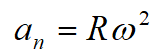

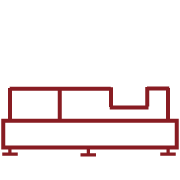

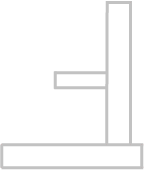

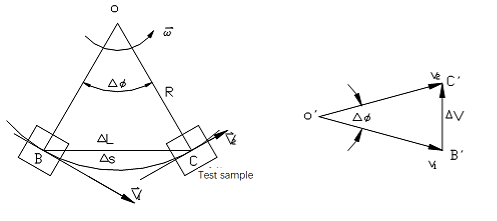

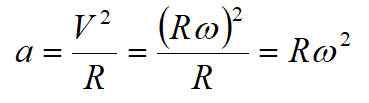

The kinematic analysis model of the constant acceleration testing machine of constant velocity circular motion is shown in Figure 1 and Figure 2.

Figure 1 Diagram of transverse acceleration of constant velocity circular motion Figure.2 Diagram of velocity vector

The test sample is installed at the testing machine R. When the velocity of the centrifuge does not change, the test sample makes a uniform circular motion relative to the ground.

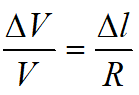

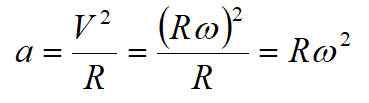

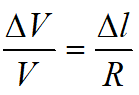

(1)

(1)

Bec

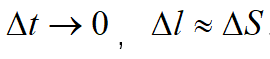

so  , when

, when

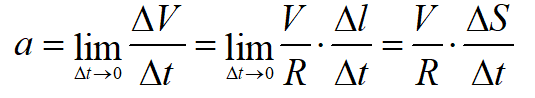

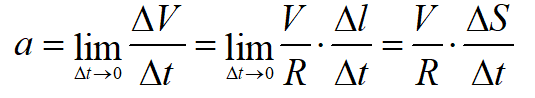

Therefore, acceleration

(2)

(2)

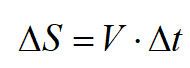

And  , therefore

, therefore

(3)

(3)

In the above formula:

—— corresponding to the linear speed of rotation at t1;

—— corresponding to the linear speed of rotation at t1;

—— corresponding to the linear speed of rotation at t2;

—— corresponding to the linear speed of rotation at t2;

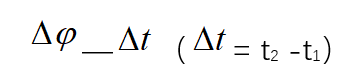

the turning angle within the time.

the turning angle within the time.

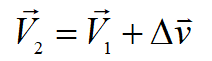

By the formula (2), the acceleration direction when  ,

,  and therefore

and therefore  , point to a rotating shaft.

, point to a rotating shaft.

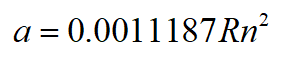

2. The mathematical relationship of acceleration, RPM, and installation radius

The same mathematical relationship exists between the acceleration, RPM and the calculated installation radius for both box centrifugal and arm centrifugal.

(4)

(4)

In the formula: a- acceleration value, g (1g=9.8m/s2);

R—Calculate the installation radius of the sample, m;

n—Rotation speed of rotating arm (disk), r/min.

3. Tangent acceleration

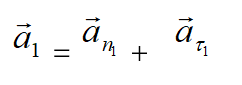

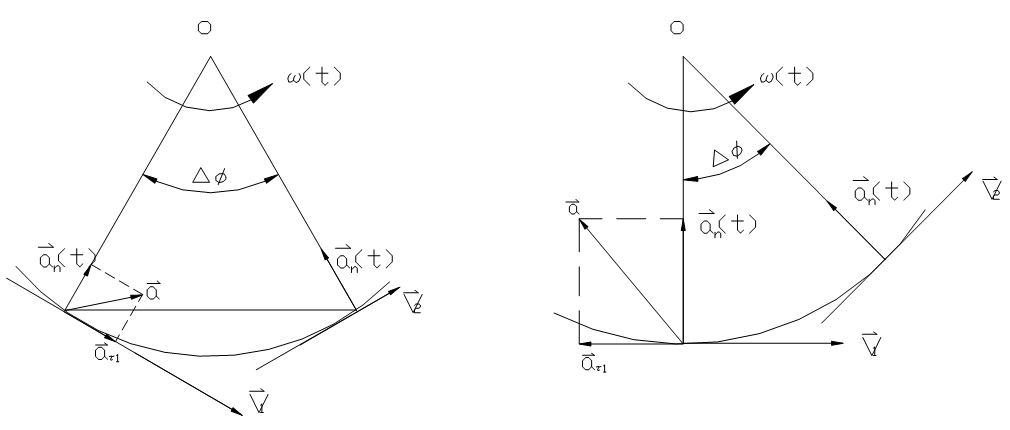

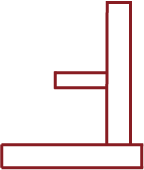

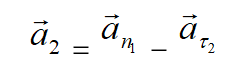

During the start-up process of the centrifuge, the test sample on the centrifuge is subjected to tangential acceleration in addition to normal acceleration. The same applies when the centrifugal testing machine decelerates. In addition to the normal acceleration, the test sample on the testing machine also bears the opposite tangential acceleration when the speed is increased, as shown in Figures 3 and 4.

When accelerating:  (5)

(5)

When decelerating:  (6)

(6)

In the above two cases, if the tangential acceleration is large, it will produce unfavorable factors for reproducibility. First, the direction of acceleration deviates seriously from the direction to be assessed. Second, the acceleration value may be greater than the specified test acceleration value. The mechanism of action of this kind of test equipment must have stages of increasing and decreasing speed. This is inevitable  . In order to reduce the impact of

. In order to reduce the impact of  , we hope

, we hope  the smaller the better. However, considering that the test time cannot be too long, some standards provide that the acceleration and deceleration time should not be less than 15s, and there are also provisions to change the speed at a speed

the smaller the better. However, considering that the test time cannot be too long, some standards provide that the acceleration and deceleration time should not be less than 15s, and there are also provisions to change the speed at a speed

Figure 3 graph of acceleration when RPM increased Figure 3 graph of acceleration when RPM decreased

4. Ripple of speed

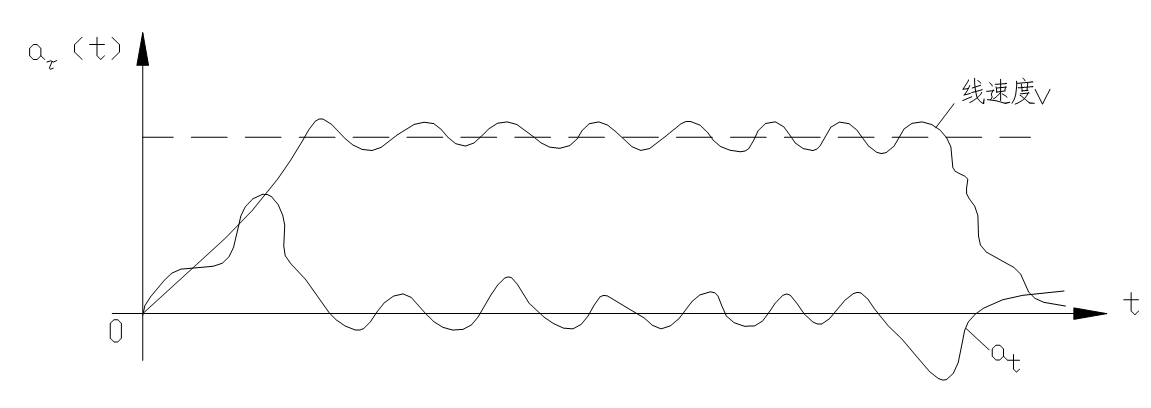

At the beginning and end of the test, the acceleration will change discontinuously due to the effect of increasing and decreasing the speed. It may also exist when you want to maintain a constant speed. The transmission part of some test equipment is unstable, such as a transmission mechanism with a large gap, unstable friction, electric rotation, unstable bearings and transmission, unbalanced mass, mechanical characteristics and tropism of the spindle, etc., will be  at this time, the time history of the speed and the value of

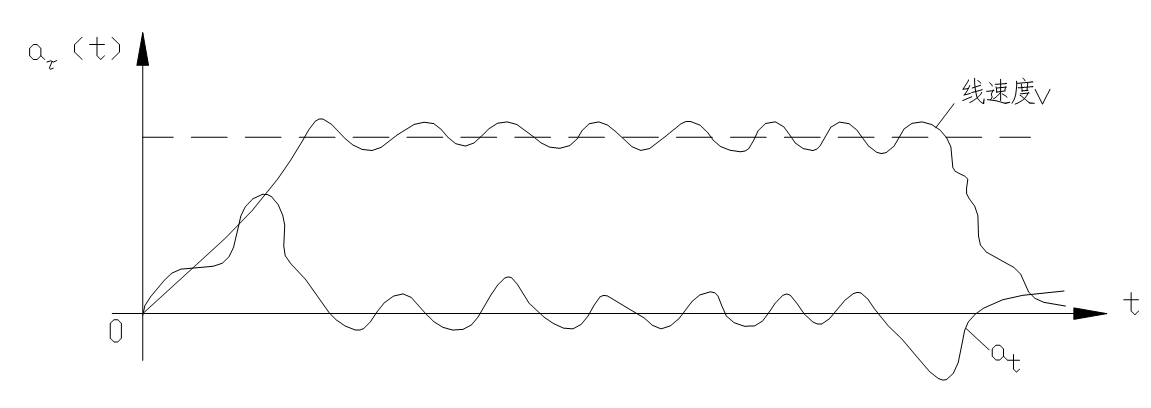

at this time, the time history of the speed and the value of  is shown in Figure 5.

is shown in Figure 5.

Figure 5 Speed with ripple component

When the constant acceleration is not a constant value and a certain frequency ripple appears, it may bring serious consequences to the reproducibility of the test. Especially when a certain natural frequency of the test sample resonates with it, this problem is more serious. Therefore, in the design and maintenance of the centrifuge, sufficient attention should be given to minimize the ripple component.

5. Acceleration gradient

When a centrifuge is used for a constant acceleration test, the constant acceleration generated is proportional to the distance between each part of the test sample and the rotating shaft.

(7)

(7)

The test sample has a certain geometric size. When the test sample is fixed on the centrifuge, the distance between each point on the test sample and the center of the rotating shaft is different, so the bearable acceleration value during the test is also different.

(2)

(2)  (3)

(3)

(6)

(6)

is shown in Figure 5.

is shown in Figure 5.