What is the shock response spectrum test?

— Part 2 Shock response spectrum test methods

1. Shock response spectrum specification:

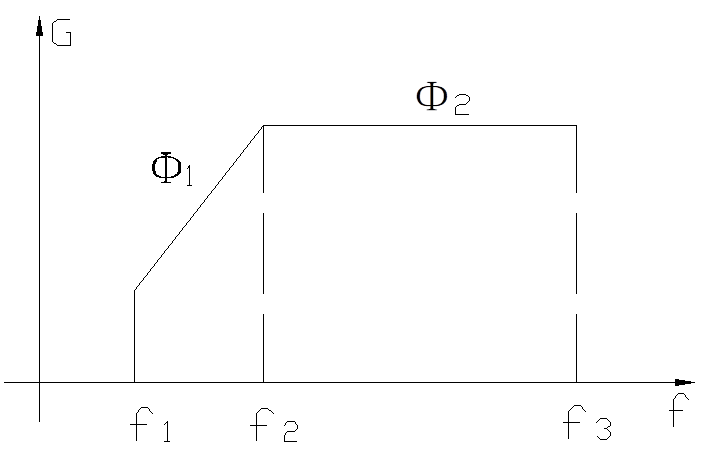

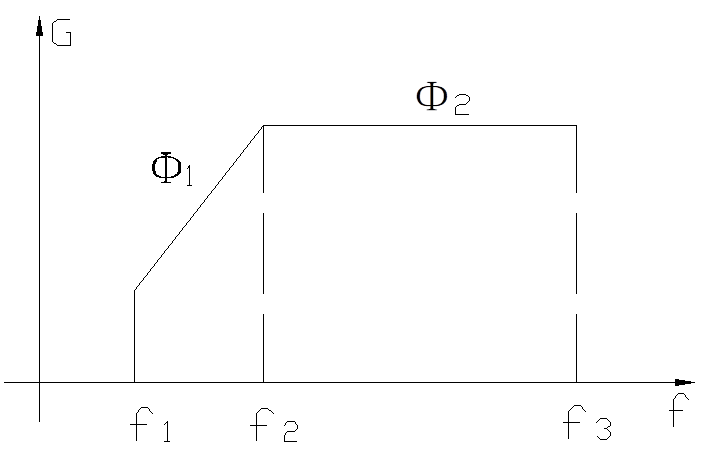

The shock response spectrum specification is similar to the traditional shock specification. It also has a standard specification curve with upper and lower tolerances. The judgment of the quality of the test is based on whether the generated shock response spectrum is within the tolerance range specified by the specification. Figure 1 is a standard shock response spectrum curve, f1 and f3 are the upper and lower limits of the analysis frequency, f2 is the inflection point frequency, and φ1 and φ2 are the slopes of the curve.

This figure specifies that when the frequency of the test product is lower than f2, the response peak value increases as the frequency increases. When the frequency exceeds f2, the response peak value will not increase with the increase in frequency. Therefore, the most important technical indicator of the shock response spectrum is the inflection point frequency.

The upper and lower tolerances of the response spectrum specification are slightly different in different countries. For example, the US military standard stipulates that it is 0~3000Hz, the tolerance band range is ±6.0dB, and the tolerance band above 3000Hz is +9.0/-6.0dB.

Figure 1 Standard diagram of shock response spectrum

2. Shock response spectrum test methods

1) Explosion method of pyrotechnic device

2) Mechanical shock method

3) Vibration table simulation method

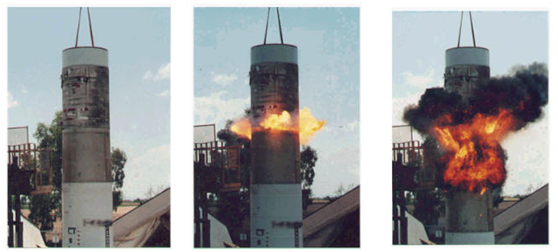

1) Explosion method of pyrotechnic device

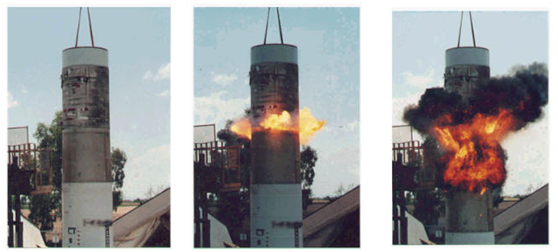

For self-generated shock or system-level tests, the actual pyrotechnic device and the formal section structure are generally used for separation tests. For the simulation of the shock environment of other near-zone explosions, the most common pyrotechnic device is to connect the flexible shaped explosive strip to the edge or back of the steel plate, and install the test piece on the plate according to the actual use state.

The advantage of the pyrotechnic product explosion method simulation test technology is that it can produce the most accurate simulation results, and can produce the high acceleration and high frequency range unique to the near-zone explosion shock environment. The main disadvantages are high test cost, poor safety and large dispersion of loading levels.

This kind of simulation test technology is mainly used in the explosive shock environment in the near area, the shock spectrum magnitude is above 1x104g, and the main frequency component is higher than 10kHz.

2) Mechanical shock method

The main principle of the mechanical shock simulation test device is to use a mass to shock another specially designed response structure, so that the shocked device generates a response environment similar to the explosion shock.

Most of these devices use pendulums, free-falling masses, pneumatic pistons, projectiles or other elastically accelerated projectiles to hit another structure (such as plates, beams, rods or composite structures, etc.) to generate a transient response environment. By dynamically designing the response structure or changing the supporting conditions, and then controlling the amplitude and time width of the shock force, the structure can produce the corresponding shock spectrum.

The main advantages of shock simulation equipment are relatively low operating costs, good repeatability, and high predictability of loading levels, but they have some limitations in their ability to generate shock spectra. This kind of simulation test technology is mainly used in the explosion shock environment of the middle and far areas. The magnitude of the shock spectrum is generally below 1x104g, and the frequency range is generally below 10kHz.

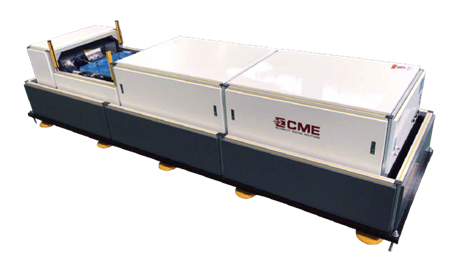

KRD15 Pneumatic Horizontal Shock Response Spectrum Test System

3) Vibration table simulation

With the development of vibration table control technology, shock spectrum that simulate low-amplitude complex shock environments have been realized on the vibrating table, such as wavelet synthesis and sinusoidal attenuation simulation methods in shock response spectrum control. Electric vibrating table and electro-hydraulic vibrating table have the advantages of equipment specification, low operating cost and high controllability. However, there are certain shortcomings in the simulation with the vibrating table: one is that its frequency range (below 3kHz) is not wide enough; the other is that the acceleration value is limited and can only simulate low-energy explosive shocks. Sometimes in order to increase the test level, a reasonable design of tooling and fixtures can obtain a higher amplification factor. The third is that the simulation of the explosion shock environment is not real enough, and the synthesized waveform is often not a transient shock, and even a certain amount of over-testing, which needs attention.

Electrodynamic Vibration Shaker