DATE: 2022-06-14

VIEW COUNT: 934

What is packaging test?

Packaging test is to evaluate or confirm the packaging of products, according to the influence of actual working conditions on unloading, transportation, packaging, or internal products obtained in the laboratory.

Packaging test is the test and measurement of related characteristic or property involved with packaging. This includes packaging materials and components, packaging shapes, shipping containers and unit loads, as well as the associated processes and environments.

Packaging test evaluates the suitability of packaging for product cushioning or supporting materials. The packaged product goes through a series of tests to determine whether the packaging material can protect the product from damage. Packaging test can be performed on an individual box or entire shipping container to measure unit load and movement during transportation.

Why do packaging test?

Packaging test is an important way to ensure the safe transportation of products from the warehouse to the customer site. Packaging test has several purposes, such as:

1. Packaging test is a basic requirement for the transportation of any product

2. Packaging integrity and product protection are essential functions of packaging

3. To measure the impact, vibration, and compression resistance of packaging and products

4. Packaging test can verify the suitability of the packaging and improve the current packaging; avoid excessive packaging and save costs

5. Packaging test can simulate the potential damage to the product during actual shipment and better protect the product safely to the destination

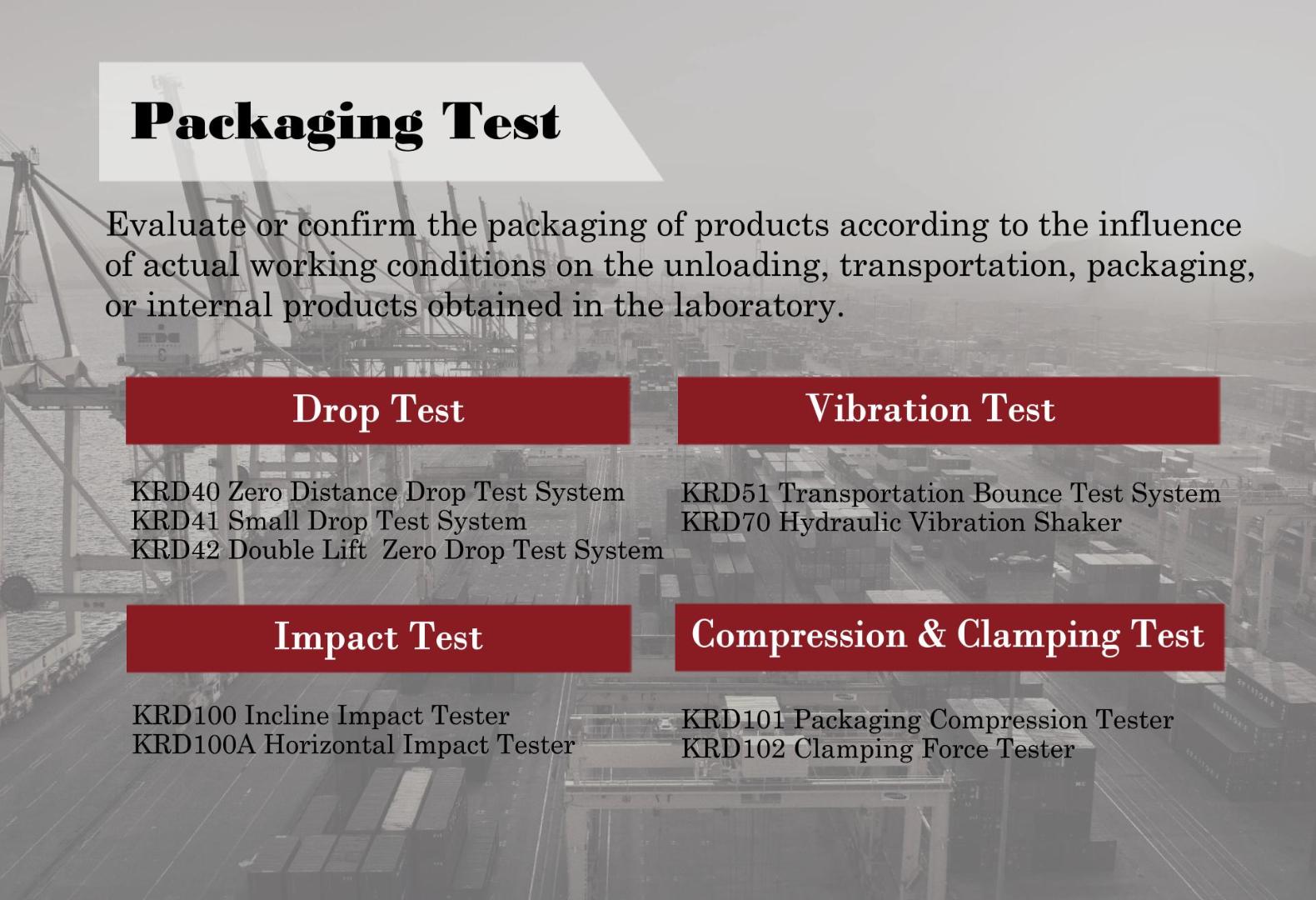

CME provides customers with packaging tests in the following mechanical environments: Drop Test, Impact Test, Vibration Test, Compression & Clamping Test.

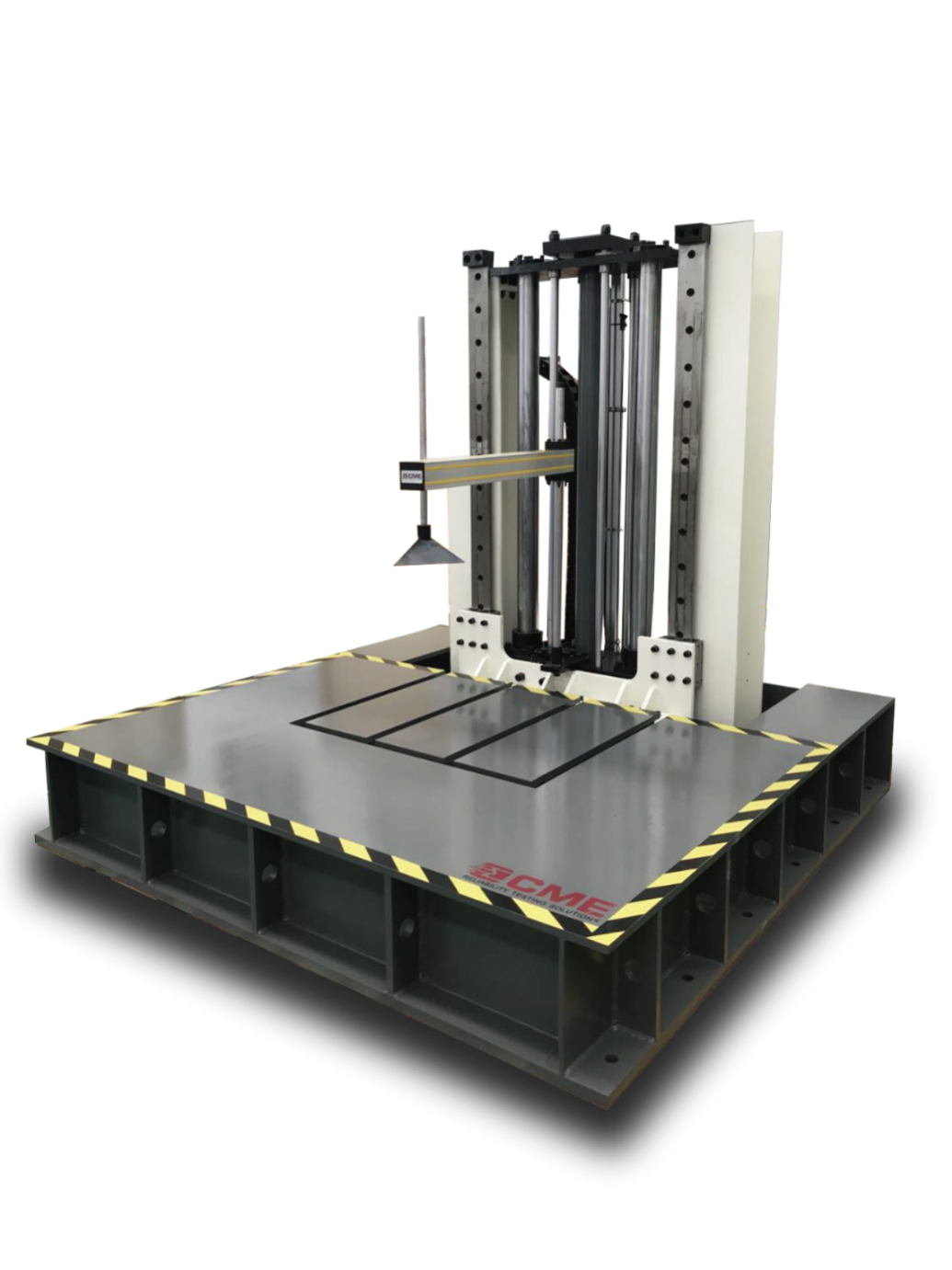

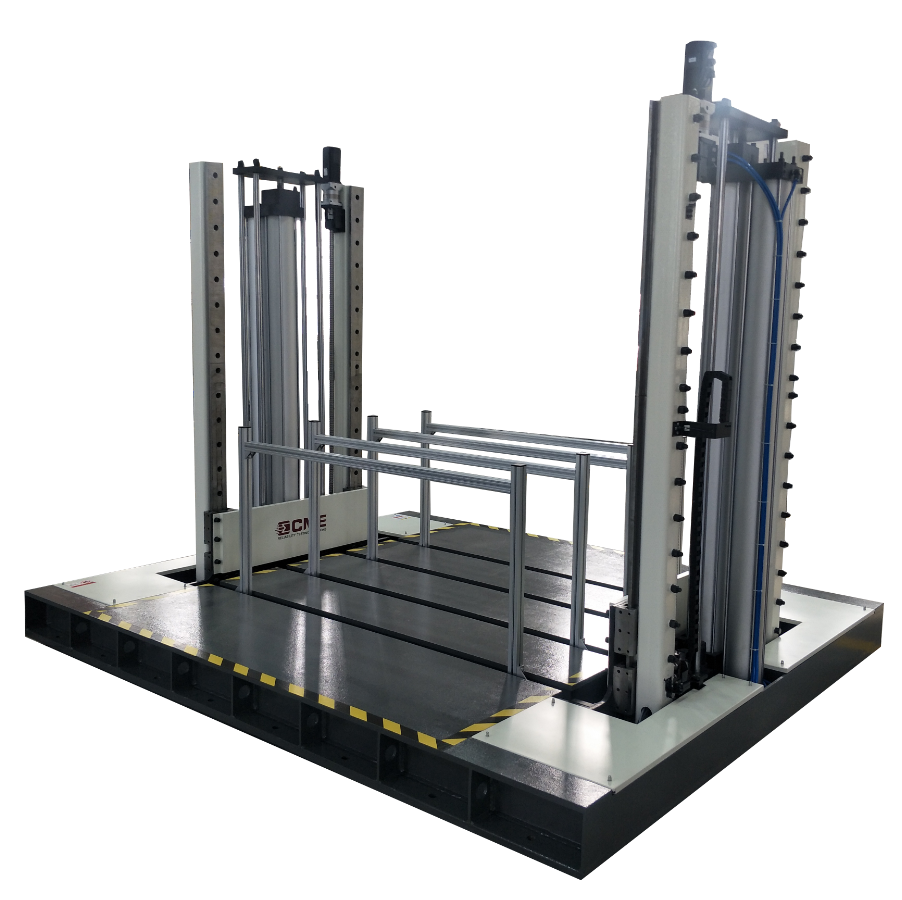

PART 1 Drop Test

Drop test simulates the free-fall impact drop that a product or packaged product may experience during transportation and loading and unloading. Drop test is mainly used to evaluate the ability of a product or packaging to withstand drops during transportation and loading and unloading, so as to improve product and packaging design.

#ISO2248 #IEC68-2-27 #ISTA #IEC 60068-2-32 #ASTM D5276

CME provides the following drop test equipment:

KRD40 Zero-distance Drop Test System mainly simulates the resistance to drop and impact of large and heavy packaging products.

KRD41 Small Drop Test System, with a minimum drop height of 300mm, suitable for free-fall test of small electronic products and components.

KRD42 Double-lift Zero Distance Drop Test System is mainly suitable for large size packaging products to resist drop impact performance.

PART 2 Vibration Test

Vibration test is one of the most important reliability tests in various industries. Many industries need corresponding standards to assess vibrations in the actual environment, thereby optimizing the product structure.

CME provides the following vibration test equipment:

KRD50 Transportation Simulation Test System

Transportation simulation (broadband random vibration), simulation of tertiary and fourth highways.

#GB/T4857 #QJ/T815 #QJ/T815 #GJB150

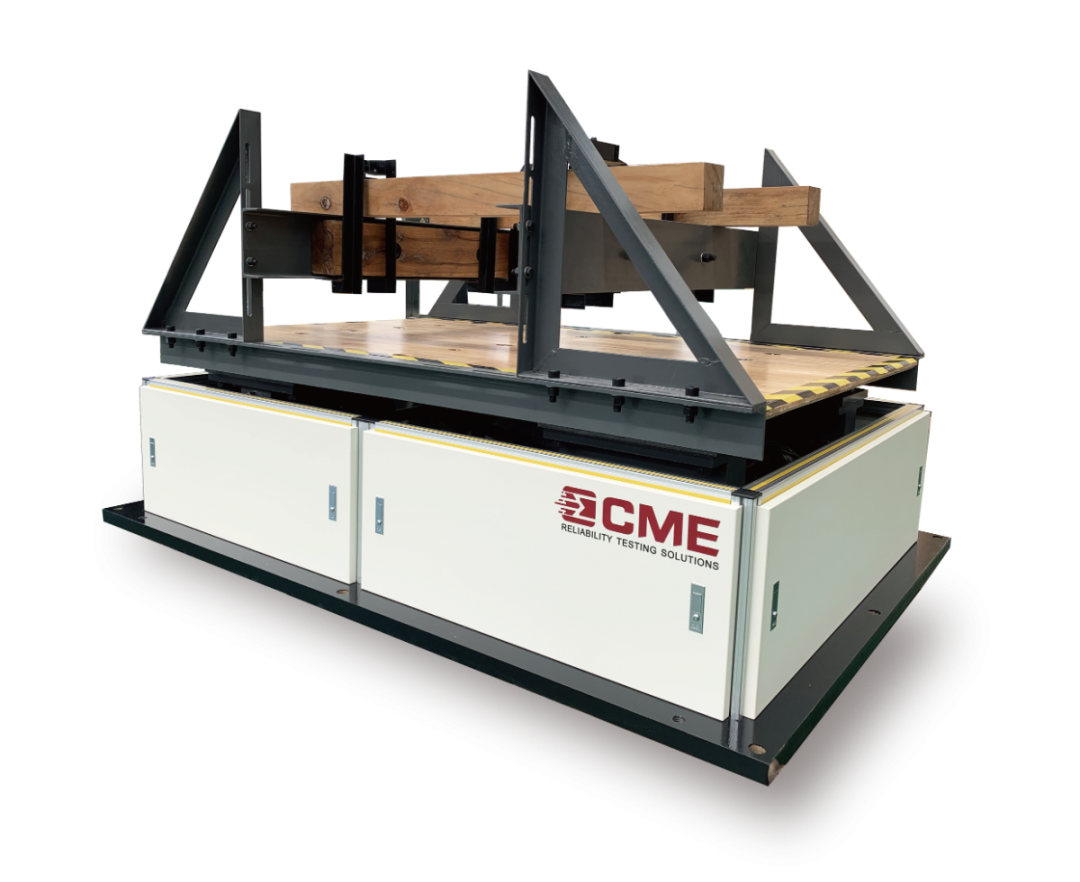

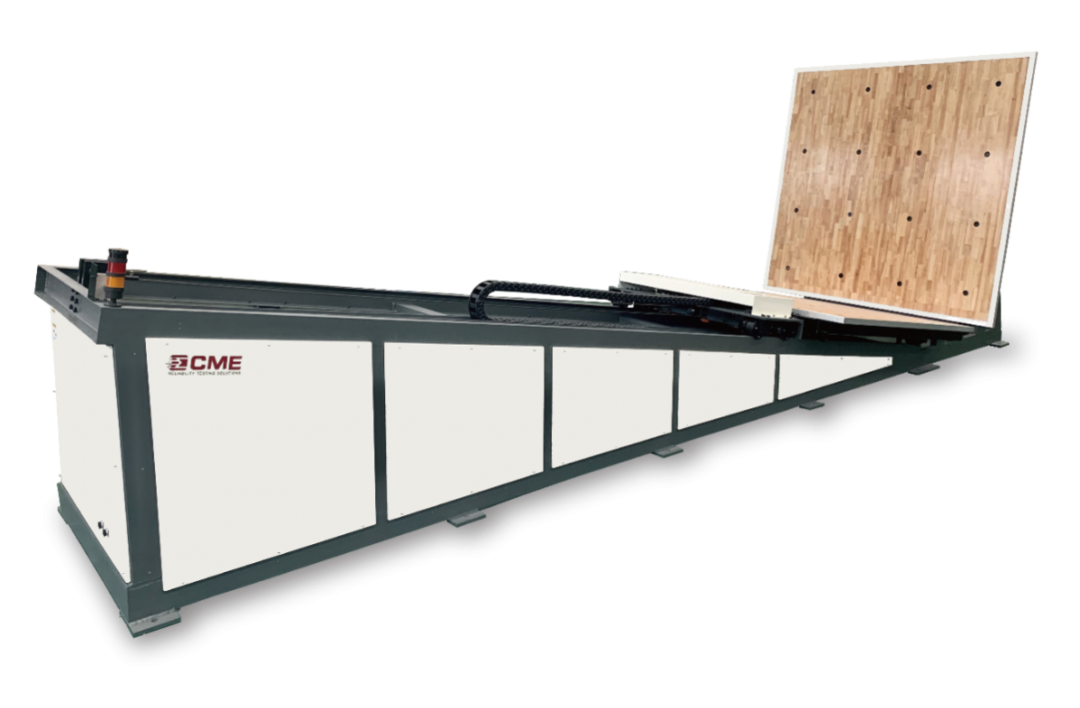

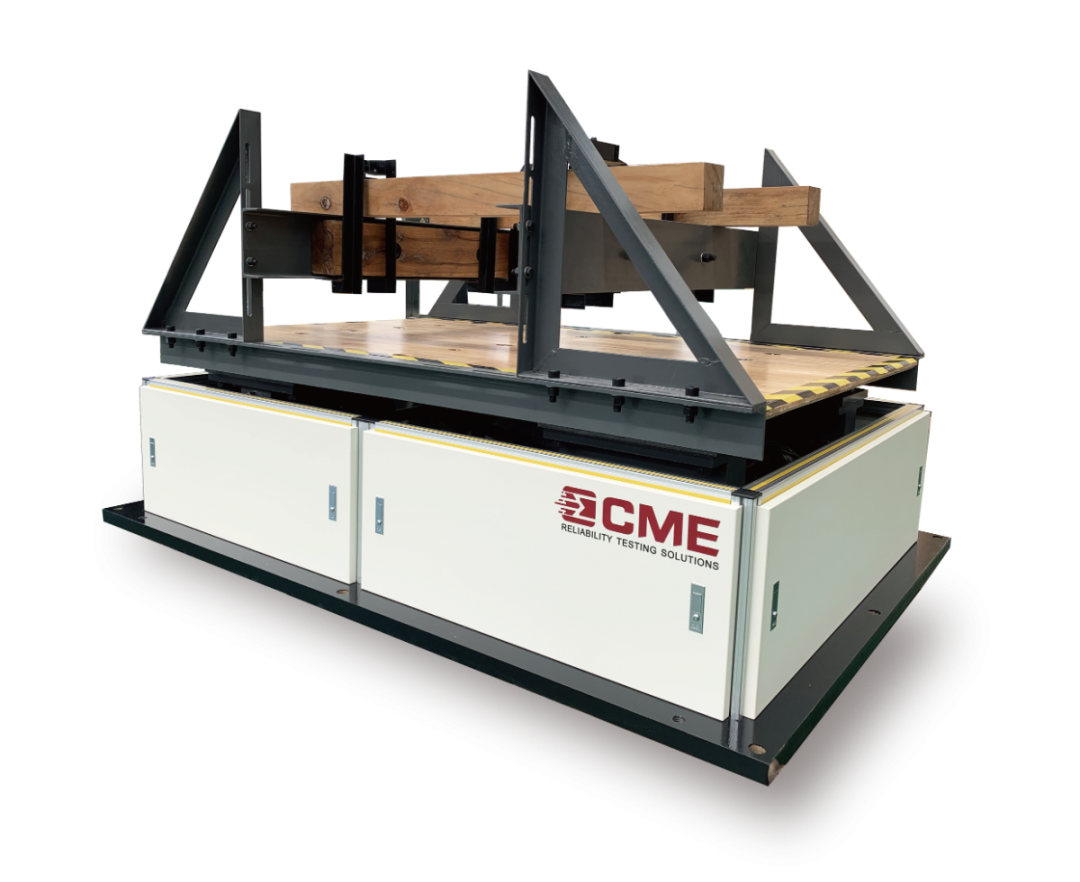

KRD51 Transportation Bounce Test System

It can simulate the loose cargo state during truck transportation with fixed displacement 25.4mm (P-P).

ISTA #IEC 60068-2-55 #MIL-STD-810 #ASTM D999 #ISO 2247

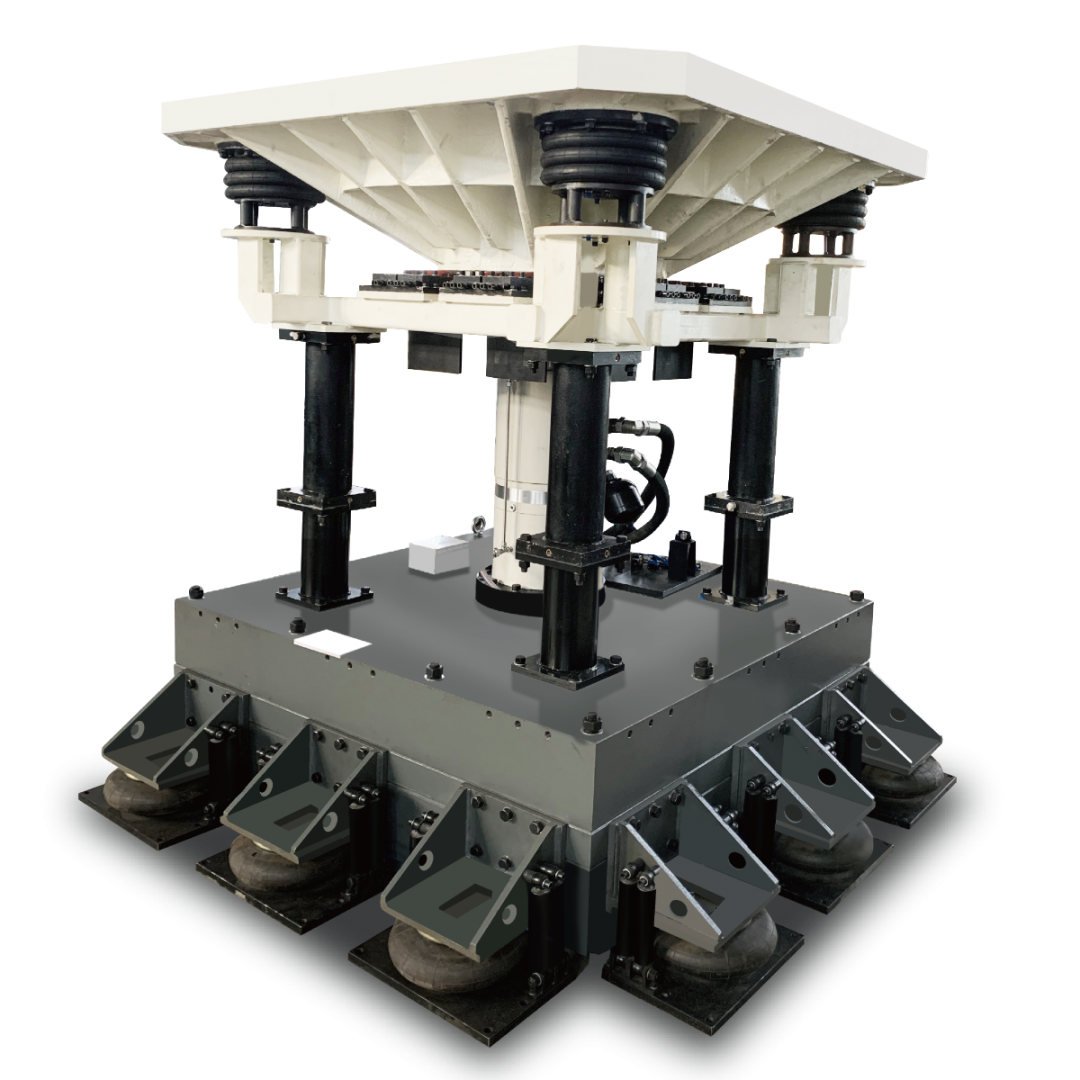

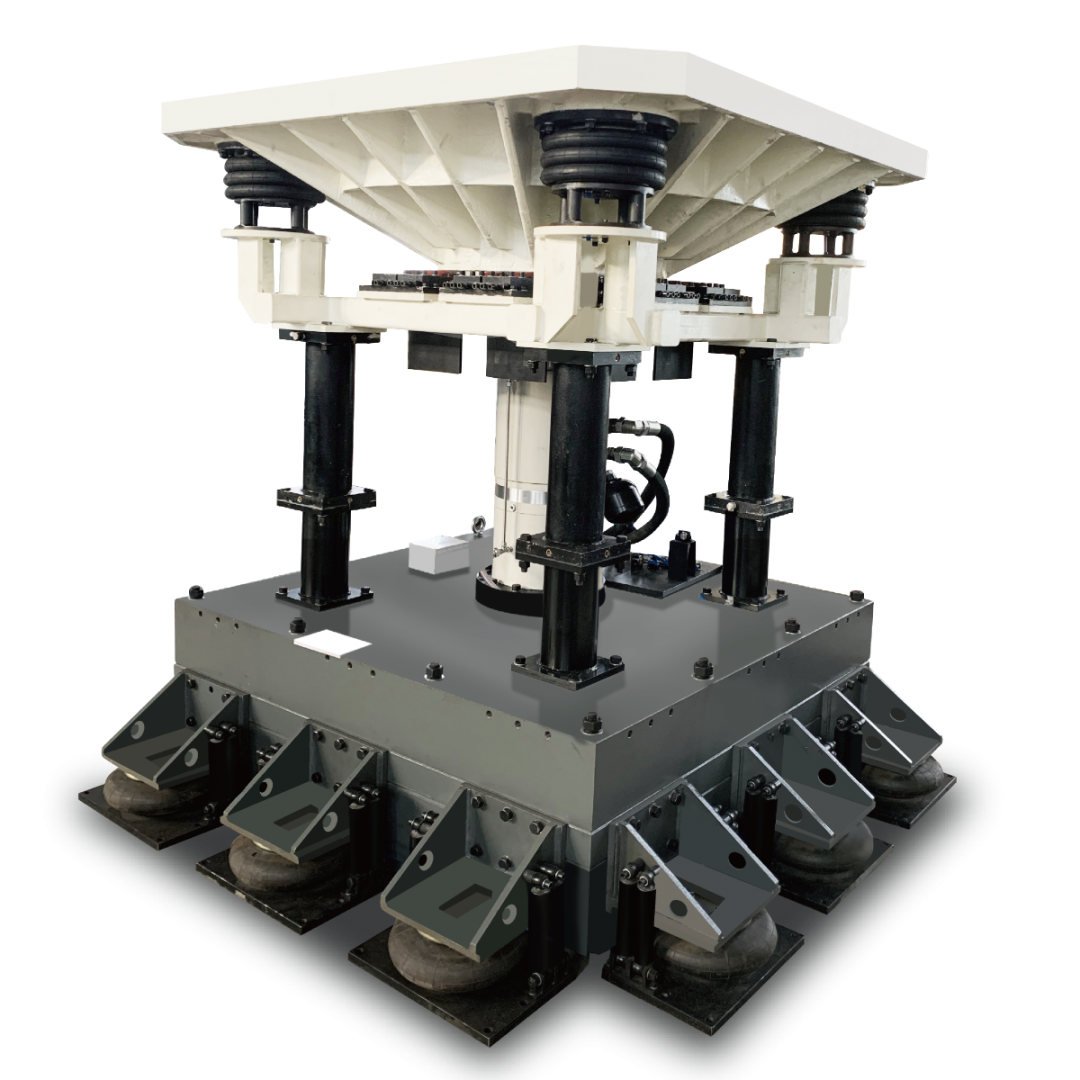

KRD70 Hydraulic Vibration Shaker

- Sine, random and road spectrum simulation vibration tests

- Low frequency to 0.1 Hz

- Meets ISTA conditions 1,2,3,6 curve requirements

- Maximum displacement up to 200mm(P-P)

- High force capability

#ISTA #MIL-STD-883 #MIL-STD-202 #MIL-STD-750 #ASTM D999

PART 3 Impact Test

Impact tester simulates the ability of product packaging to resist shock damage in the actual environment, such as handling, stacking of shelves, sliding of motors, loading and unloading of locomotives, product transportation, etc.

CME provides the following two types of impact test equipment:

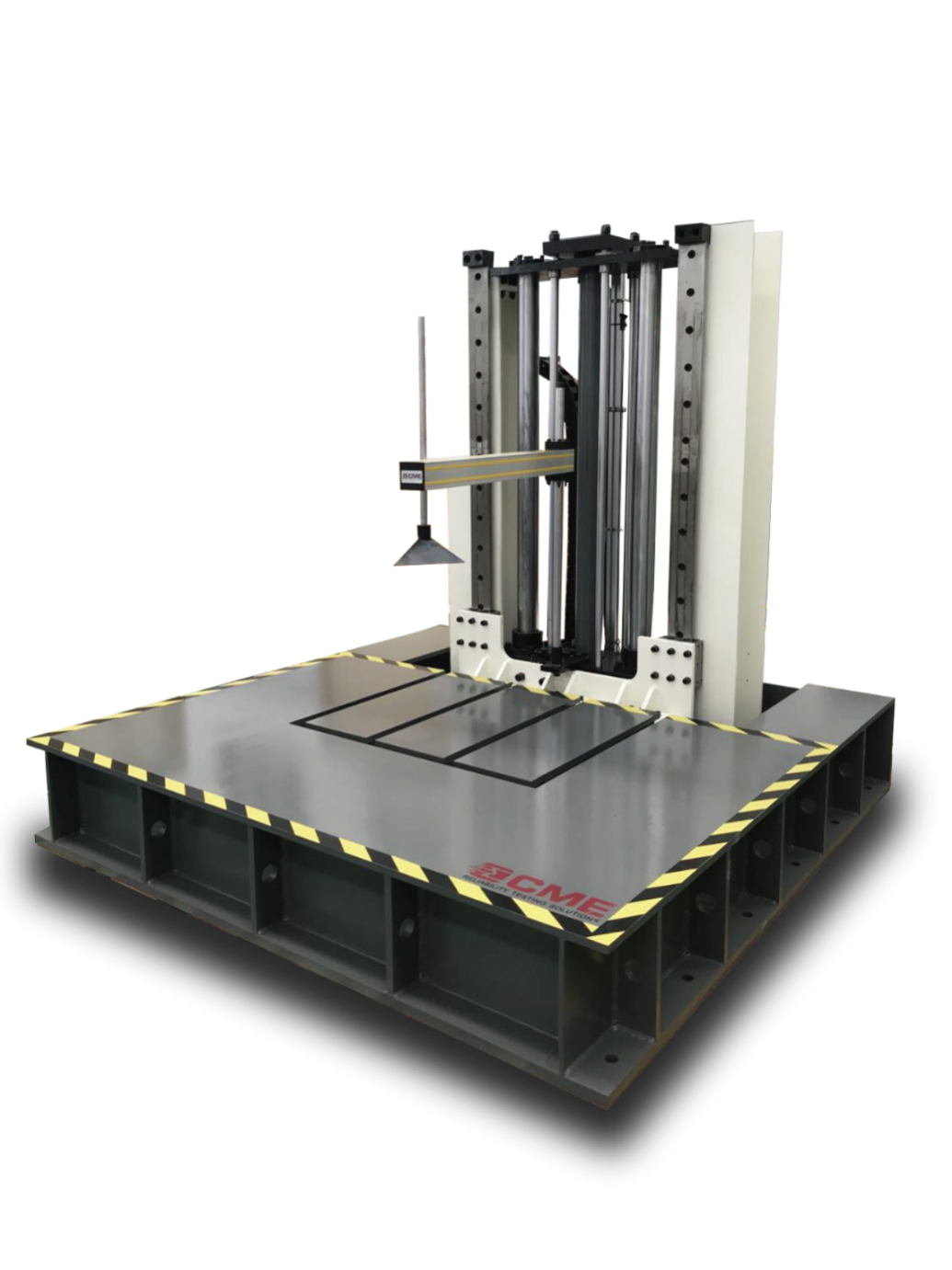

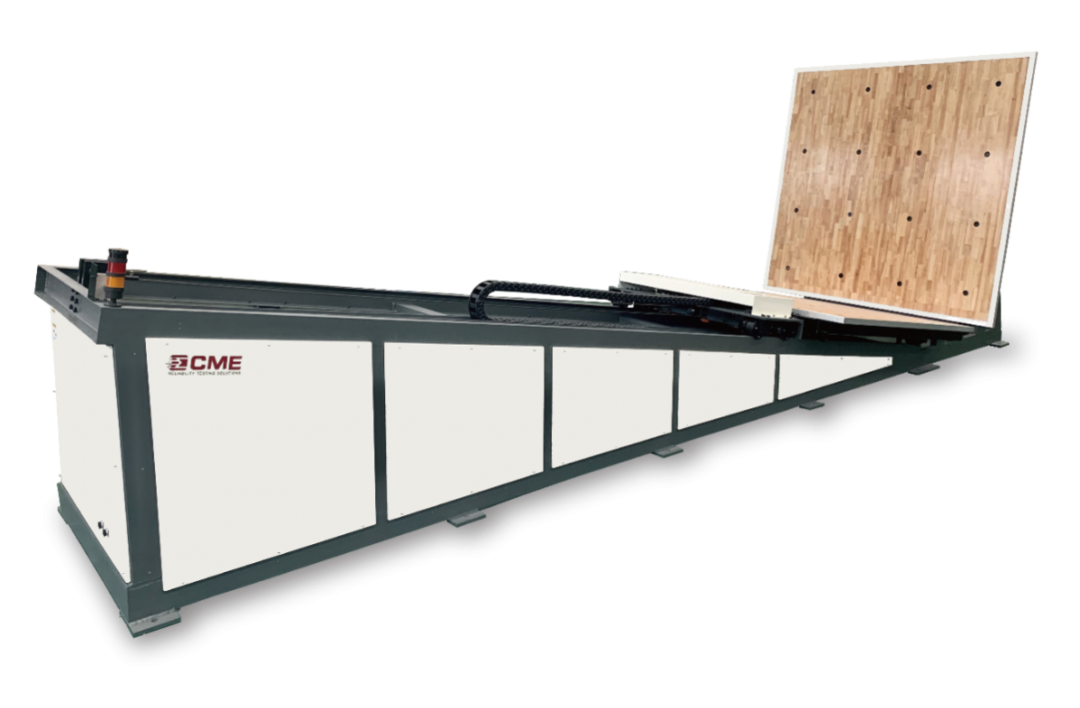

KRD100 Incline Impact Tester

KRD100 Incline Impact Tester can simulate the incline impact and collision environment of packages and containers during transportation.

#ISO 2248 #ISTA #ASTM D880 #ASTM D5277

KRD100A Horizontal Impact Tester

According to standard ISO 2244 - Packaging-Full shipment packaging and component shipment - horizontal impact test.

# ISTA # ASTM D4003 # ASTM D880 # ISO 2244

PART 4 Compression & Clamping Test

KRD101 Packaging Compression Tester

KRD101 Series Packaging Compression Tester is designed to evaluate the compressive strength of packaging in order to prevent the product from deforming or being damaged during handling, stacking, storage, and transportation due to insufficient packaging strength.

# ISTA #ASTM D642 #ISO 2874 #ISO 2872 #ISO 13820

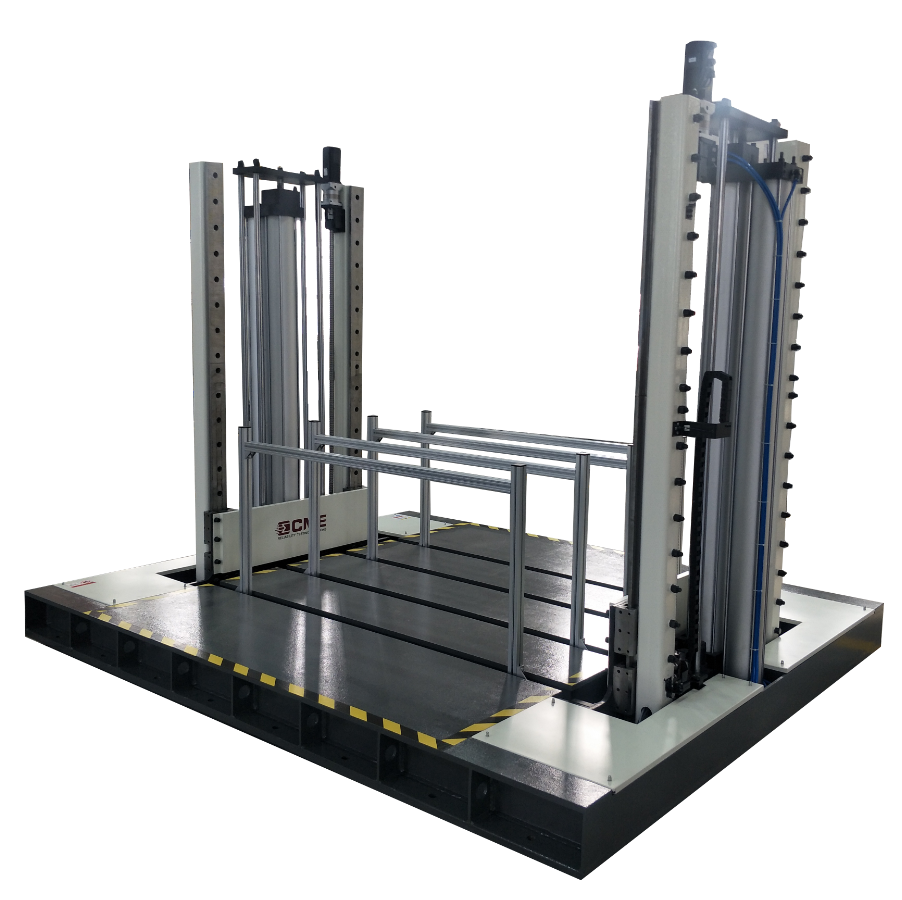

KRD102 Clamping Force Tester

KRD102 Series Clamping Force Tester can simulate the situation that the goods in the container are clamped when they are transported from the container to the warehouse. Whether the goods are damaged due to the clamping, so as to evaluate the anti-clamping ability of the packaging.

#ISTA #ASTM D6055 #SEARS

Contact us for all packaging test needs!